WELCOME

2024 was a breakthrough year for TenCate. It marked the large-scale rollout of a product that we believe represents the future of synthetic turf. The positive market response to Pure PT, or Pivot® as it is known in the US, has been really rewarding to see. Given the years of research and testing we dedicated to developing it, we’re proud it is now being enjoyed by people across the world.

“Circularity and sustainability are vital elements of our approach to innovation.”

— Michael Vogel, CEO

HIGHLIGHTS FROM 2024

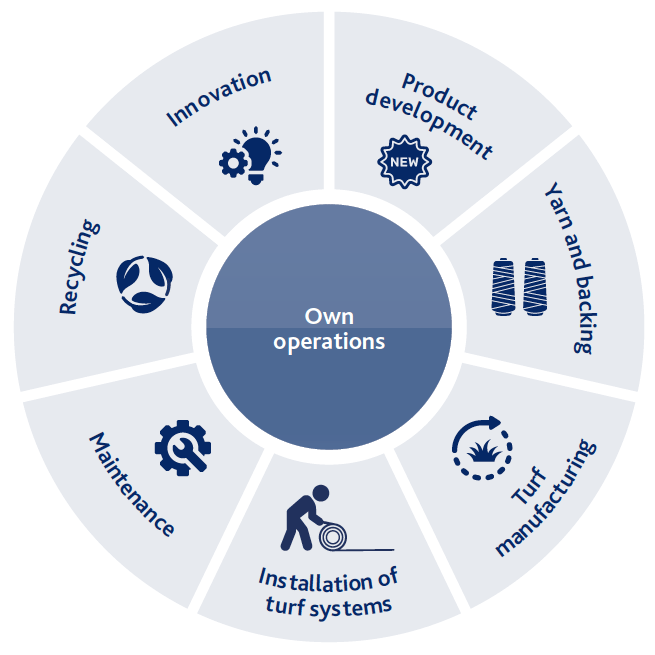

BUSINESS MODEL

INNOVATION & DEVELOPMENT

TenCate’s long-term success is rooted in our continuous focus on innovation. Our dedicated Center for Turf Innovation (CTI) leads our R&D process, developing new products and optimizing existing ones. The CTI puts turf components and systems through a rigorous process of testing, refining, due diligence, and validation. Our innovations help us improve the performance, durability, safety, and sustainability of synthetic turf systems, and launch innovative new products and technologies such as Pivot®, Pure PT and ONE-DNA™.

YARN & BACKING MANUFACTURING

To create a synthetic turf system, you first need to manufacture yarn (to make the grass-like strands) and backing (to hold the turf together). TenCate offers a wide range of high-quality synthetic turf fibers designed for different applications, from sports to landscaping meeting customers’ varied needs in terms of yarn color, thickness, texture, shock absorbance and more. Produced to the highest standards, our yarns and backings can be used to create good-looking, durable, high-performing turf systems.

TURF

MANUFACTURING

At this stage in the manufacturing process, yarns and backings are tufted and transformed into turf “carpet”. Our turf systems are designed with the right properties to meet customers’ and users’ specific needs, whether the turf is destined for a sports field, a play area, a golf course or a landscaping application.

INSTALLATION & MAINTENANCE

From the factory floor to the application itself. We work with customers to design and install the right solution for them, whether that’s a no-infill turf system, or an infilled turf system with materials such as sand, cork or rubber. Beyond turf, we also design and install other sports surfaces including athletics tracks and tennis courts. We offer turnkey solutions that make the installation experience as smooth for our customers as possible, including construction of fencing and lighting. Once our product is installed, we offer ongoing customer support, repair and maintenance services.

END-OF-LIFE

RECYCLING

When turf reaches end-of-life, we seek to preserve the value of those raw materials. Through partnerships with companies such as ExxonMobil and GBN, we have recently become more directly involved with turf recycling helping to close the loop and support the circular economy.

COMPANIES & LOCATIONS

13 COUNTRIES – 42 COMPANIES – 4200 EMPLOYEES

OUR SHARED VALUES

TOGETHER FOR A SUSTAINABLE FUTURE

At TenCate, we unite people, innovation, and sustainability. With strong products, dedicated teams, and partners, we’re building a future focused on performance and respect for our planet. Together, we make a difference.

A great product means nothing without the people behind it

We’re proud of our 4,200+ employees in 13 countries. They extrude the yarn, weave the backing, build the systems and install the fields. They are TenCate.

- World-Class Workplace: Named one of the best global employers of 2024–2025

- 93% feel safe at work, and 82% feel inspired by our mission

- Gender equality in focus: 25% of senior leaders (C-suite -1) are women

- DEI in practice: From open dialogue to multilingual training and safe complaint mechanisms

- Real training, real growth: From Dubai to Dallas, we tailor safety and skills programs to each site’s needs

And we keep improving, because people make the turf perform.

Better turf, by design

We didn’t just remove the infill. We rethought everything. Pure PT (aka Pivot® in the US) is the most sustainable turf system we’ve ever built and maybe the most tested in turf history.

- Infill-free: No rubber. No sand. No microplastics. Just performance.

- Natural feel: Designed using biomechanics and validated by elite athletes

- Durable: Outlasts standard systems by 30% backed by 12-year warranty and Lisport XL tests

- Efficient: Up to 75% lower maintenance costs and 80% fewer transport movements during install

- Versatile: Installed from California to Curaçao, for sports, schools, municipalities and more

- Recyclable: Easier end-of-life processing thanks to single-polymer design (ONE-DNA™ ready)

Whether it’s high-stakes football or weekend play, Pure PT is changing the game.

Turf that respects the ground it covers

We know our products are made of polymers. That means we carry responsibility. Here’s how we take that seriously:

- 94% waste diversion at our manufacturing sites (goal: 90% met and exceeded)

- Zero PFAS in all production since early 2024

- Internal recycling systems now reuse up to 50% of extrusion waste

- Zero water hockey fields replace millions of liters annually

- NO infill means NO microplastic migration and easier maintenance

- ONE-DNA™ tech enables fully circular reuse at end of life

- CO₂ cut at every step: From lighter products to local manufacturing to fewer truckloads

We’re not perfect. But we’re moving forward, fast.

PROGRESS

2024 wasn’t just a busy year. It was a breakthrough year.

- Pure PT launched globally and surpassed expectations for performance and adoption

- 6 trucks needed for a Pure PT install vs 22–32 for traditional fields

- 13 countries, 42 companies now part of TenCate Group

- World-Class Workplace label achieved based on employee feedback

- Lisport XL passed at 500,000+ cycles with minimal wear

- 6.3 million liters of water saved per hockey field

- Major waste-to-value advances, including EcoNailer and circular turf reuse

- Full Scope 1, 2 and 3 GHG emissions baseline now published

- CSRD readiness underway with next DMA planned for 2025

This is what progress looks like when ESG isn’t a separate track — it’s part of how we work.

We can’t do ot alone

TenCate collaborates with global and local partners to scale innovation and impact:

- Johan Cruyff Foundation: 227+ inclusive sports fields installed for kids worldwide

- ExxonMobil & Cyclyx: Advanced chemical turf recycling in the US

- LimeGreen: Launch of ONE-DNA™ landscape turf across EU and North America

- PSV Eindhoven: Ongoing R&D partnership with elite athletes at the Herdgang Academy

- FDDK Curaçao: Installed FIFA-certified Pure PT pitch for national stadium

- Tomorrowland: Circular turf pilot installed, used and recycled post-festival

We share knowledge, we share tech and we play it forward — together.

THE ROAD AHEAD

We remain dedicated to driving continuous improvement and innovation in our ESG practices. Our objective is to generate long-term value for all stakeholders while advancing a more sustainable future. I encourage everyone to review the report, take pride in our accomplishments, and consider how we can further elevate our impact moving forward.

“Led by our values, we are focused on continuing our ESG journey, with a clear roadmap for the coming years.” — Nikoleta Konstantinidou – Group ESG Director

ESG REPORT 2024

We are pleased to present our 2024 ESG Report, which highlights our commitment to sustainable and responsible practices. This report emphasizes our efforts to create a more sustainable future for the industry and reflects our dedication to generating long-term value for stakeholders while positively impacting society and the environment.

Discover how we foster sustainable growth and create impact.

Want to see how far we’ve come? The 2023 report highlights the foundations we’ve built, from early innovations to the initial major strides toward circular turf systems.